Project Description

Why Aluminum Oxide Materials Are More Expensive than Mill Finish

Introduction:

Aluminum oxide materials, known for their superior durability and corrosion resistance, often come with a higher price tag compared to mill finish aluminum. This article aims to shed light on the factors contributing to the higher cost of aluminum oxide materials.

Surface Treatment and Finishing:

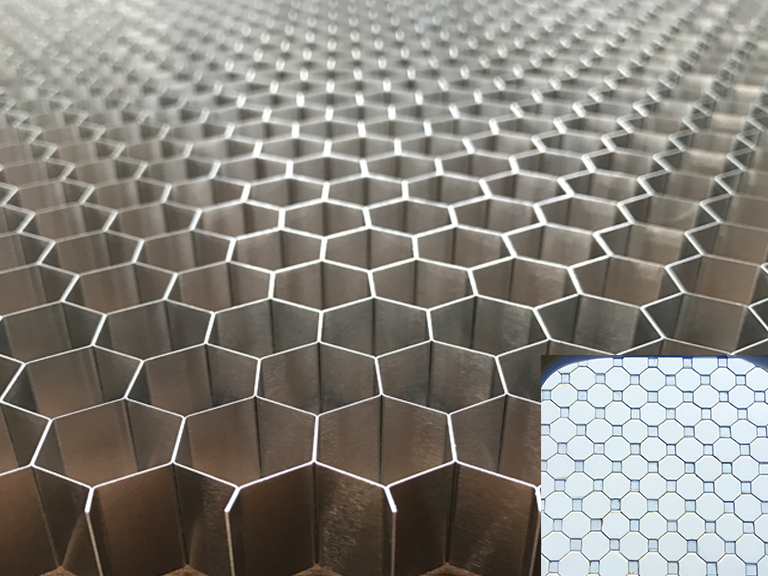

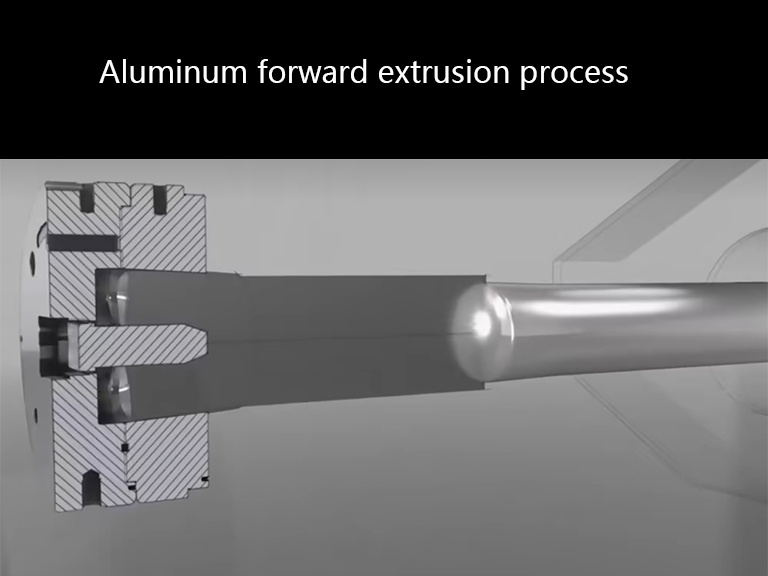

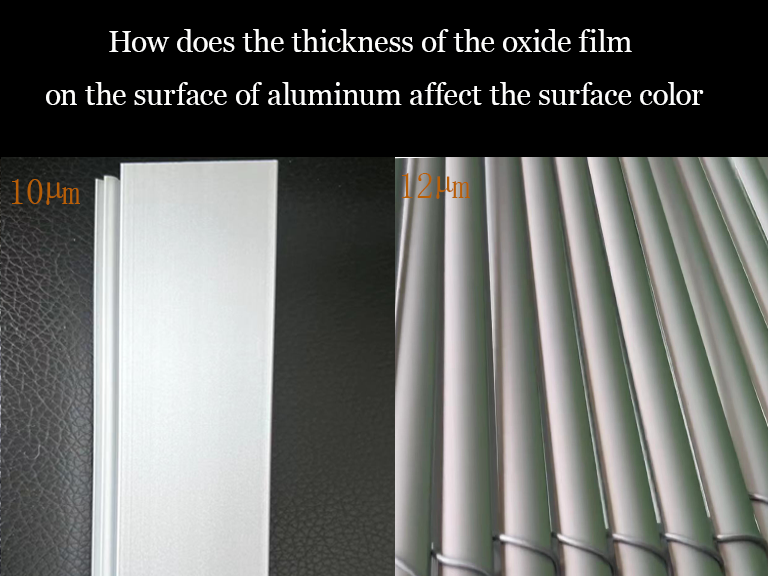

Mill finish aluminum refers to the raw, untreated surface of aluminum, which undergoes minimal processing. In contrast, aluminum oxide materials involve additional surface treatment and finishing processes. Aluminum oxide can be achieved through anodizing, a process that forms a protective oxide layer on the surface of aluminum. This additional treatment and finishing increase the production cost of aluminum oxide materials.

Enhanced Durability and Corrosion Resistance:

Aluminum oxide materials possess superior durability and exceptional resistance to corrosion compared to mill finish aluminum. The anodization process creates a thick and robust oxide layer, providing a barrier against external elements and enhancing the material’s longevity. The improved properties make aluminum oxide materials ideal for applications in harsh environments, contributing to their higher cost.

Specialized Applications:

Aluminum oxide materials find extensive use in specialized industries that require enhanced performance characteristics. These applications include aerospace, automotive, electronics, and construction. The unique properties of aluminum oxide, such as its high hardness, excellent electrical insulation, and thermal resistance, make it suitable for demanding applications. The specialized nature of these applications drives up the cost of aluminum oxide materials.

Precision and Customization:

Producing aluminum oxide materials often involves precision processes and customization to meet specific requirements. This includes controlling the thickness of the oxide layer, achieving specific colors through dyeing, or incorporating additional coatings. These additional steps require specialized equipment, skilled labor, and precise quality control, all of which contribute to the higher cost of aluminum oxide materials.

Limited Availability:

The production of high-quality aluminum oxide materials is more intricate and resource-intensive than producing mill finish aluminum. Anodization facilities and expertise are limited, resulting in a relatively lower supply compared to the demand. The limited availability of aluminum oxide materials drives up the cost due to factors like increased production time and higher resource allocation.

Conclusion:

The higher cost of aluminum oxide materials compared to mill finish aluminum can be attributed to factors such as additional surface treatment and finishing, enhanced durability and corrosion resistance, specialized applications, precision requirements, and limited availability. Understanding these factors helps explain the price difference and highlights the value and unique characteristics that aluminum oxide materials offer in various industries.

If you have any questions, please feel free to contact us. We will respond as soon as possible.