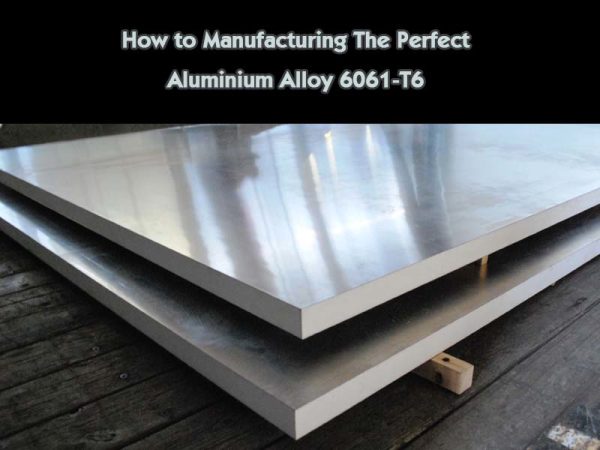

Project Description

Brief Introduction:

Alloy 5052 Aluminium Sheet is of Al-Mg Alloy, and one of the most widely used antirust aluminium. Alloy 5052 has high strength especially the fatigue strength; it has plasticity and high corrosion resistance, cannot heat treatment. In the cold work, it has good hardening plasticity, good weld ability and can be polished.

Application:

Alloy 5052 Aluminium Sheet is widely used in the high request of plasticity and good weld ability, working in a liquid or gas medium as low load parts such as post box, gas or oil duct, other various liquid container, and making of small load parts such as rivet. It also commonly used to stamping parts of transport vehicles and ship, instrument, streetlight holder and electrical enclosure, etc.

Mechanical Property:

Tensile Strength (σb): 170~305MPa

Offset Yield Strength: σ0.2 (MPa)≥65

Elasticity Modulus (E): 69.3~70.7Gpa

Annealing Temperature: 345℃

Surface Finish:

- Not allowed to have a crack, corrosion spots and nitrate on surface.

- Not allowed to have peeling, bubble, rough surface and mechanical damage.

- Allowed the supplier to polish the surface along the lengthways.

- Other requirements: the two parts of supplier and demander determine on its own.

Welding Electrode Model:

Alloy 5052 Aluminum Sheet should be welded by ER5356 welding electrode, after welding, it can satisfy the mechanical properties of alloy 5052 aluminum sheet.

The Distinguish Aluminum Sheet between Alloy 5052 and Alloy 1060:

Hardness:

tensile strength of alloy 1060 is 110-130, however alloy 5052 is 210-230. That means alloy 5052 is much harder than Alloy 1060.

Percentage of elongation:

Alloy 1060 is 5%, however alloy 5052 is 12%-20%, that means under the circumstances alloy 5052 is harder than alloy 1016, and the elongation of alloy 5052 has improved by 200%.

Chemical Properties:

Alloy 1060 is pure aluminum, alloy 5052 is Al-Mg alloy, in exceptional circumstances alloy 5052 has better corrosion resistance.