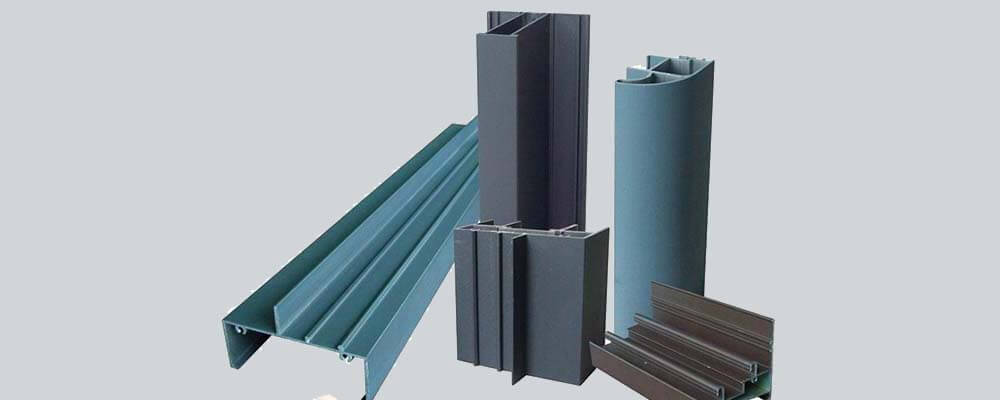

Project Description

The aluminium powder coating process is electrostatic guns spray the powder to the aluminium section surface,under the electricostatic field,to form the powder coating.Powder coating aluminium profiles go through high temperature oven, forming the final coating.

The surface treatment of aluminium profiles are mainly anodizing, electrophoresis,powder coating, each treatment technology have its own advantages and its own market share. Compared with anodizing technology, the powder coated technology have its advantages as following:

1.Powder coating technologies of aluminium section are simple and the coating quality mainly depends on the automation and accuracy control during the production. Main parameters on aluminium extrusion profile powder coating have realized microcomputer control, which greatly reduced the operation difficulty and auxiliary equipment.

2.The powder coating techniques of industrial aluminium profile feature with high yield rate and low demand on surface treatment. Generally with proper operation of the aluminium extrusion process the yield rate can be increased and the energy consumption decreased.

3.The anodizing and electrophoretic coating is energy and water intensive process, especially electrophoretic coating. The current output reach 8000-11000A and voltage 15-17.5v, adding the heat produced by machine itself, the aluminium extrusion process require constant water circulation and electric consumption around 1000KW.

4.Anodizing aluminium section pollute the environment

5.The automatic operation of aluminium profile coating production line and the simplification of the loading mode and the use of clamp have increased production capacity and lowered the labor intensity.

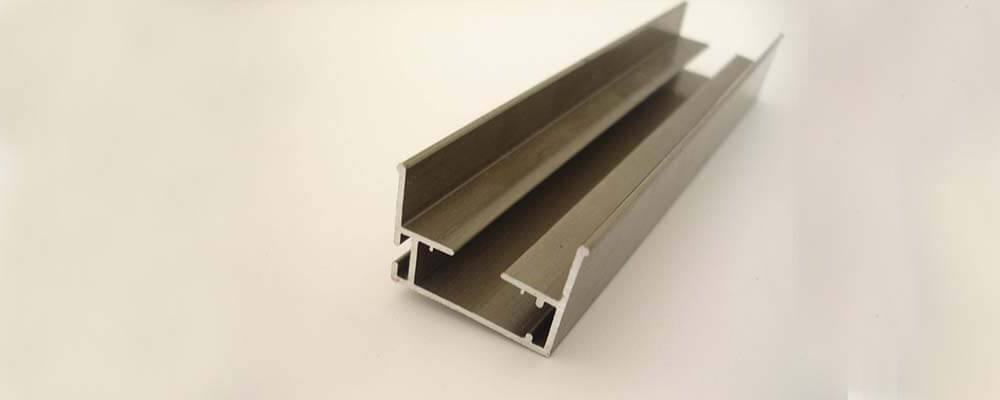

6.The powder coating of aluminium extruded profiles have low demand on the aluminium bars surface. The powder coat can cover surface flaw of aluminium profile and make the surface better appearance.

7.Life span of aluminium profile section can be prolonged for the powder coat enhance the hardness and abrasive resistance of aluminium extrusion profile.

8.The various powder coating colors meet the demand of inner decoration and is in accord with the application trend of construction aluminium profiles.

Brand: HIWANT

Grade:Alloy 6000 Series.Most like 6063,6061,etc.

Temper: T3-T8.Most like T5 or T6

Surface Treatment: Powder Coating.

Certificate: ISO 9001:2008

Color: Silver, Gold, White, Black or depended on you.

Quality Standard: GB5237-2008.

Package: Shrink wrap.

Delivery: 15-20 days after deposit.

Application: constructive windows and doors, curtain walls, other various architectural.

Length: standard: 6 m or your custom

Price Terms: FOB according to your certain request

Payment: T/T or irrevocable L/C at sight